|

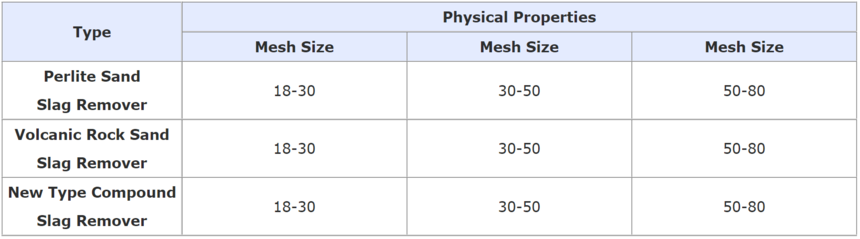

Slag Remover

Slag remover is a material used to remove impurities in molten iron or molten steel in steelmaking or casting. Its main components are SiO2, Al2O3 and so on. The general deslagging agent has the function of heat preservation and covering. Its working principle is to adsorb and accumulate various oxides in the smelting process to facilitate removal. Slag remover expands or melts under high temperature. After expansion, the specific gravity is low, forming hollow pores. At the same time, it has a certain cohesiveness, which can effectively collect and dross and slag on the surface of the metal solution. At the same time, slag remover has stable chemical properties and will not cause secondary pollution to metal solutions.

LastPetroleum CokeNextCold Box Resin |