|

Powder Coating (alcohol/water-based)Powder coating for foundry Product description 1. Foundry coating is suitable for all kinds of iron castings, steel castings and non-ferrous alloy castings, belonging to sintered peeling coating, coating and casting automatic peeling. Non-sticking sand, easy to clear sand, can reduce the casting cleaning workload. 2. It has good comprehensive performance at normal temperature and high temperature, high temperature resistance, scouring resistance, no cracking, low gas generation, high strength of coating, good air permeability and so on. 3. Good suspension, coating, thixotropy and leveling.

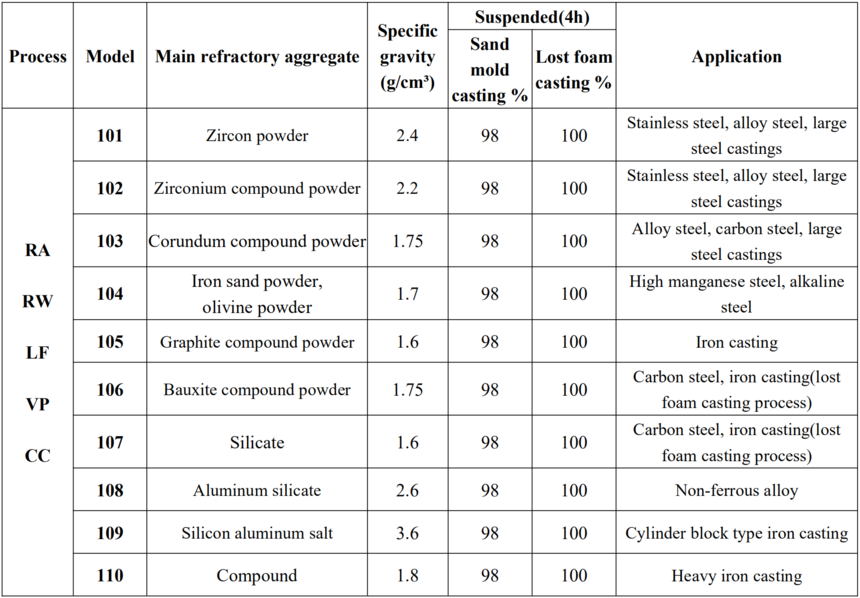

Main properties and physicochemical indexes:

Note: 1. RA is resin sand alcohol based coating (Resin Alcohol-based); RW is resin sand water based coating (Resin Water-based); LF is a special coating for lost foam casting (Lost Foam casting), also referred to “EPC process”; VP is special coating for "V "process (Vacuum Process); CC is a special coating for centrifugal casting (Centrifugal Casting). 2. All kinds of models can provide powder and wet granular coating according to demand. 3. According to the customer's different casting technology, casting material, production conditions, we can provide customers with targeted coating solutions, personalized project services.

The advantages of powder coating: 1. Lower material cost: Powder coatings cost less than liquid/paste coatings. And the solvent that adds a certain proportion is mixed in the finished product after agitate, powdery coating cost accounts for ratio lower. And because powdery coatings do not belong to hazardous chemicals, there is no need to use expensive special packaging for hazardous chemicals to save packaging costs. 2. Lower transportation costs: Because chemical alcohol solvents are flammable, alcohol-based liquid/paste coatings must be shipped as hazardous chemicals, while powder coatings can be shipped as general cargo. The transportation cost of general goods is much lower than that of hazardous chemicals. Because it contains no solvent, powdery coatings can occupy a smaller volume and weight, resulting in significant savings in shipping costs. 3. Easier procedures: Because alcohol-based liquid/paste coating is a dangerous chemical, export must wait for the commodity inspection of government departments, and customs clearance procedures are complicated, high cost. And powdery coating can press general goods export, can avoid above problem, program is simple, save time. 4. Longer shelf life: Powdery coatings can be kept in dry conditions for a long time, and solvents can be added temporarily when needed. Compared with alcohol-based liquid/paste finished coatings, the shelf life is significantly longer, which is convenient for customers' production management. |