|

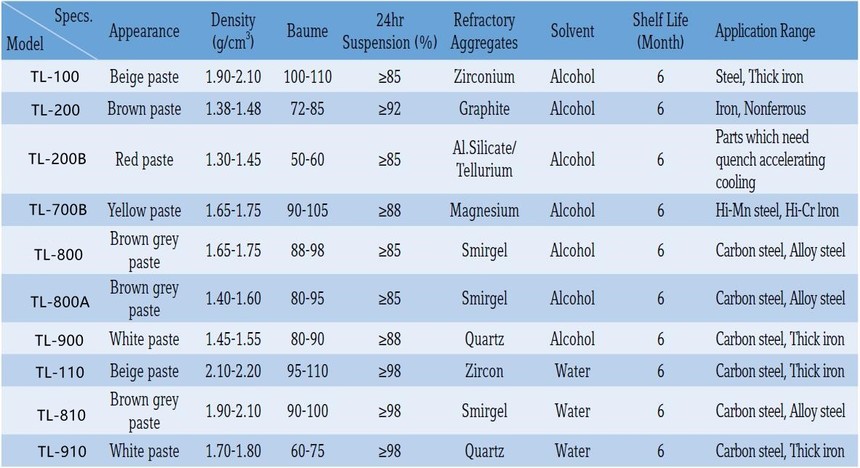

Liquid / Paste Coating (alcohol/water-based)Characteristics Excellent thixotropy and leveling property, tight and smooth coating layer, adequate room temperature and high temperature strength, guarantees the quality of the casting roughness. Low gas emission, proper shielding properties, reduce the air hole defects on the casting. The coating layer and the casting will separate automatically, decrease the cleaning work on the casting. Specifications / Models

How to use Choose the coating according to the specification, technical process and quality requirements on the castings. Fully stir before using, avoid vortex when stirring, stir fully after adding the solvent, dilute to the suitable Baume on the technique or required coating method, do some stirring during working. When use TL-200B coating, after fully stirring, coat to the section where need rapid chilling uniformly and light immediately. Stop using over one day, empty the coating before using again, wash the coating tank, the leftover coating should be filtered with screen mesh over 200 to remove impurities and sand for further use. 1kg water-based and alcohol-based coating could coat 0.7-1.0 square meter with the layer thickness of 0.2-0.3mm. Coating method: brush, dip, spray, etc. Packing and Storage Plastic drums with 50kg net weight of TL-100/110; 30kg net weight of TL-200/800A; 40kg net weight of other coatings. |