|

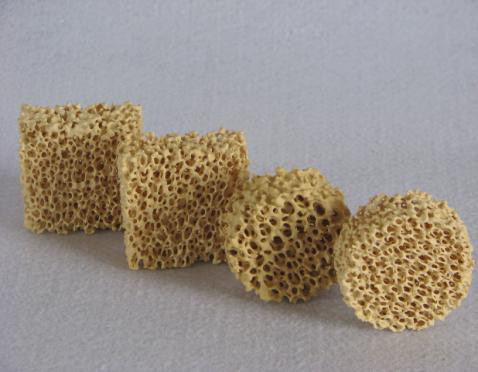

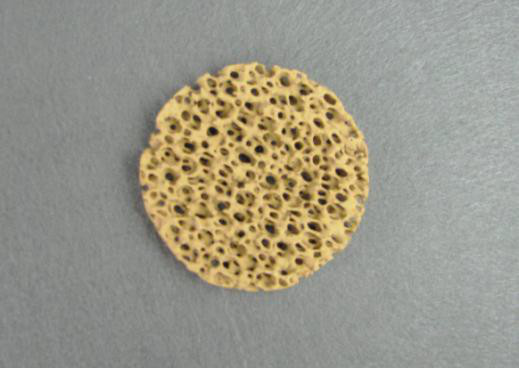

Zirconia Foam Ceramic Filter

Metal liquid filtration technology is an effective means to improve the surface and internal quality of castings. Filters have been widely used in automotive parts, aerospace, machine tools, hydraulic parts, pump valves, wind power and other industries. EUREKA's filter products, selling well in China and exporting to more than 40 countries and regions.

Product features: ◎ Excellent high temperature performance, operating temperature up to 1750℃; ◎ High strength at room temperature, not easy to drop slag; ◎ Stable quality, high porosity, good filtration effect.

Dimensions: It can be customized according to the size and shape required by users

Banding requirements: High temperature resistant fiber cotton with thickness of 1mm, 3mm and 5mm can be wrapped around the filter according to requirements. Ceramic edge wrapping products can also be customized.Maximum length and width (diameter) up to 300mm.

Usage: 1. Aperture selection Large steel castings to choose 10~ 15PPI, higher requirements for small pieces can choose a smaller aperture filter according to the demand. 2. The filter ◎ Carbon steel and low alloy steel 1.0-2.7kg /cm2 ◎ Stainless steel 1.0~4.0 kg/cm2 Filtration amount is related to casting type, placement position, casting temperature, head size and other factors. Please contact our engineer for specific application plan. 3. Size selection Diameter/side length 40~70mm, thickness 15~22mm ◎ Diameter/side length 75~100mm, thickness 22~25mm Diameter/side length 125~150mm, thickness 25~30mm Diameter/side length 175~225mm, thickness 30~35mm Diameter/side length 250~300mm, thickness 35~40mm Foam ceramic/straight hole filter method of use ◎ The filter position is as close to the casting as possible to achieve the best filtering effect. Generally, open gating system is adopted. ◎ Filtration area: the cross section of the sprue where the filter is placed must be expanded, generally 2~4 times the normal cross section of the sprue, the width of the filter support platform is 5~12mm, and the gap between the filter and the filter seat is 0.5~1mm; ◎ When multi-plate filter is used for large castings, the water flow through each filter must be balanced; ◎ The height of the buffer before and after the filter or the upper and lower buffers is recommended to be 1.5H~2.5H (H is the thickness of the filter) to prevent local overload of the filter; ◎ The casting height should not exceed 300mm when the filter is directly impacted. The filter should be properly thickened when the filter is directly impacted. ◎ The new product design filter can be put into mass production only after initial test and small batch verification that there is no abnormality.

Precautions for the use of foam ceramic/straight hole filters ◎ The filter is ceramic, it must be handled with care to prevent bumping; ◎ Before putting the filter seat in the filter must blow the filter internal debris; ◎ After putting in the filter seat, check that the top of the filter can not be higher than the parting surface; ◎ When the casting temperature is low, the zirconium filter needs preheating. Storage and shelf life of foam ceramic/straight-hole filter ◎ Storage in dry and ventilated place, no rain and heavy pressure; ◎ The handling process should be handled with care to prevent bumping and trampling; ◎ The shelf life is three years, if the storage period is more than one year, it is recommended to use after drying. |

||||||||||||||||||||||||||||||||